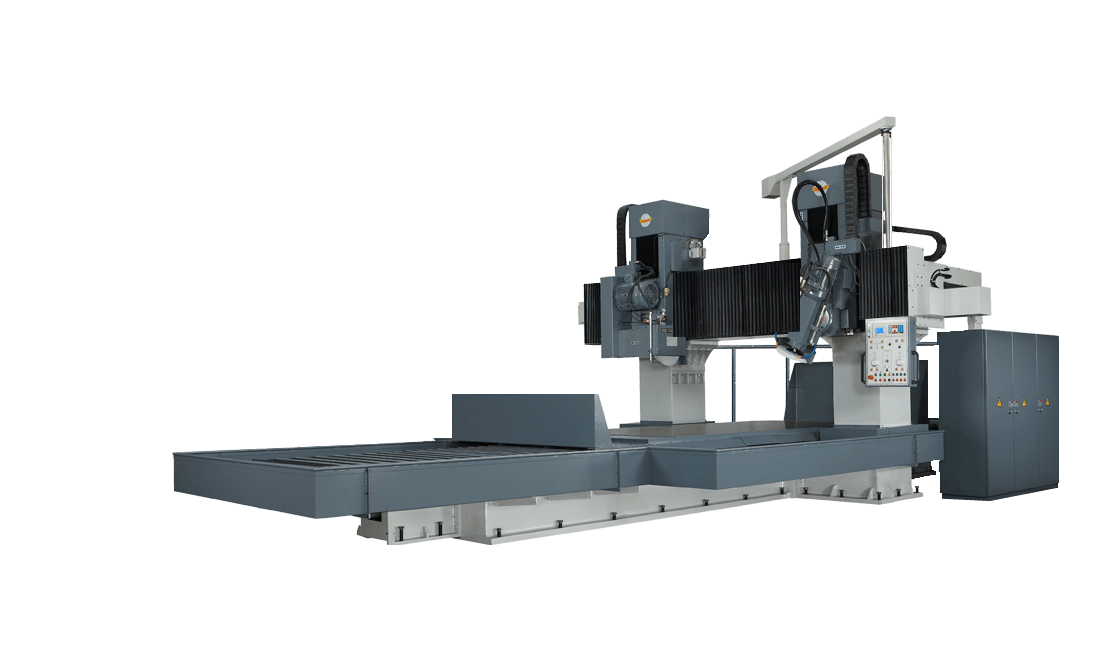

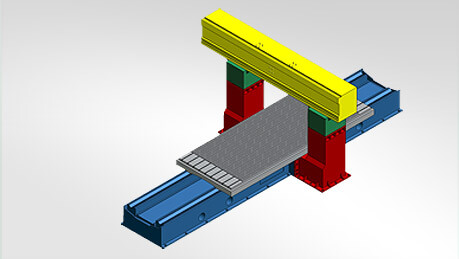

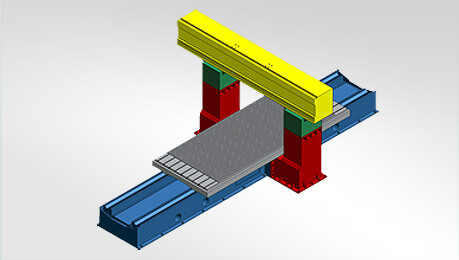

| Model | SGS-T3018PNC | SGS-T4018PNC | SGS-T5018PNC | SGS-T6018PNC | SGS-T7018PNC | |

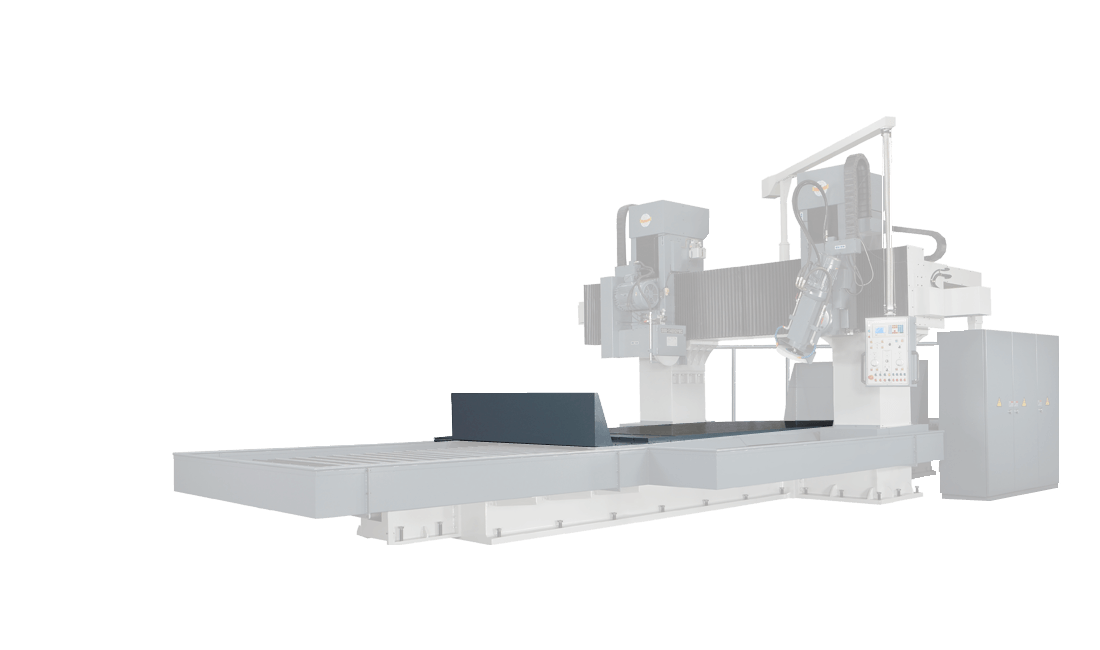

| Working Surface of table. WxL | 1800x3000 | 1800x4000 | 1800x5000 | 1800x6000 | 1800x7000 | |

|

Max. grinding surface WxL |

1900x3100 | 1900x4100 | 1900x5100 | 1900x6100 | 1900x7100 | |

| Max. Horizontal travel of table. | 3200 | 4200 | 5200 | 6200 | 7200 | |

| Distance between two columns | 2200 *2500 | |||||

| Distance between table surface and spindle center (H.AXLE) | 1150 | |||||

| Distance between table surface and wheel top (V.AXLE) | 750 | |||||

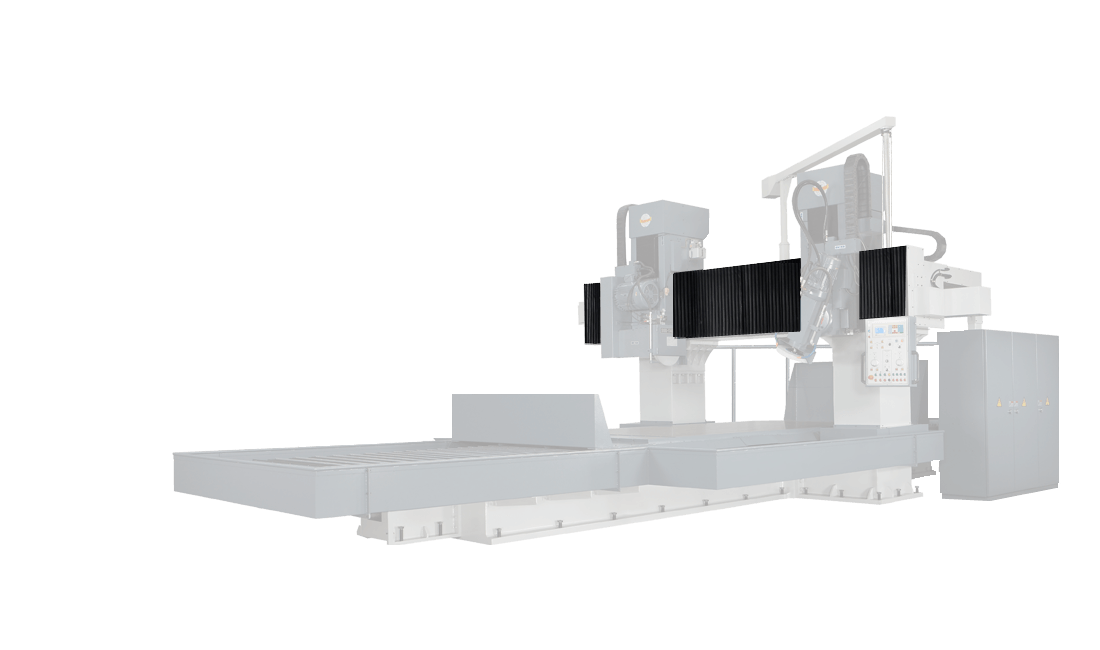

| Inclination of universal head | ± 90° | |||||

| Table speed | 5~25 M / min (16~80 fpm) | |||||

| Automatic crossfeed of spindle seat (60HZ) | 0~25 | |||||

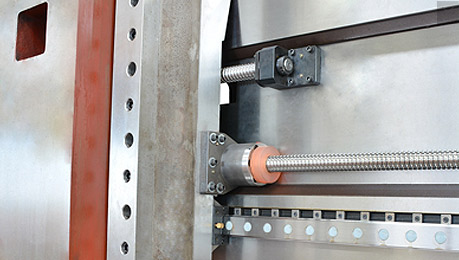

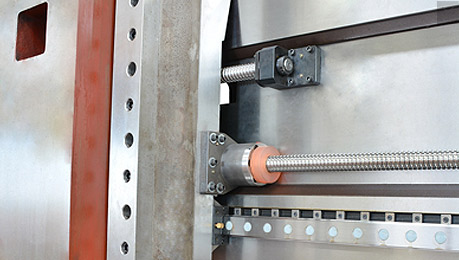

| Downfeed handwheel min scale | 0.005 *0.002 | |||||

| Crossfeed handwheel (1 gra)min scale(PNC) | 0.005 *0.002 | |||||

| Crossfeed handwheel (1 rev)pulse handle(PNC) | 0.5 -1 -4 | |||||

| Longitudinal travel adjustable (from-to) | 200~3200 | 200~4200 | 200~5200 | 200~6200 | 200~7200 | |

| Crossfeed travel adjustable (from-to) | 50~2000 *50~2300 | |||||

| Spindle motor (H.AXLE) | 20HP x 4P *30HPx4P | |||||

| Spindle motor (V.AXLE) | 10HP x 4P *15HP x 4P | |||||

| Hydraulic pump motor | 20HP x 6P | 30HP x 6P | ||||

| Crossfeed motor | AC SERVO | |||||

| Downfeed motor | AC SERVO | |||||

| Grinding wheel (ODxTxID)(H.AXLE) | 510 x 50 x 127 *510 x 75 x 203.2 | |||||

| Grinding wheel (ODxTxID)(V.AXLE) | 405 x 50 x 127 | |||||

| Spindle speed 60/50HZ(H.AXLE) | 1250 RPM | |||||

| Spindle speed 60/50HZ(V.AXLE) | 1750 RPM / 60HZ 1450 RPM / 50HZ |

|||||

| Flow rate of coolant pump | 200 L / min | |||||

| Max. load capacity | 9000 kgs | 11000 kgs | 13000 kgs | 15000 kgs | 17000 kgs | |

| Net Weight | 33000 kgs | 41000 kgs | 48000 kgs | 57000 kgs | 65000 kgs | |

In specification, if there is a * mark in front of item, it is an optional specification.

We follow a policy of continuous improvement of all our products, and reserve the rights to change specifications, mechanìcs, or designs at any time without notice or oblìgation.