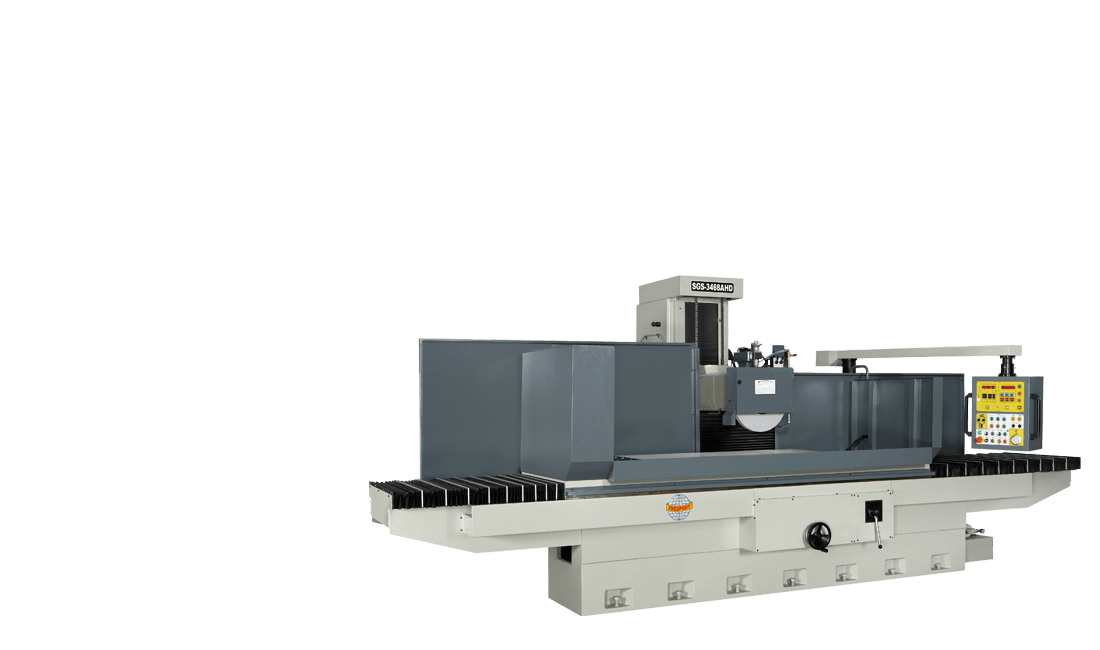

This heavy-duty series integrate NC control, AC servo motor, and solenoid valve hydraulic system into one rigid mechanism. Together with the centralized user -friendly control system, our heavy-duty series is capable of executing all types of grinding tasks with the greatest efficiency.

Heavy duty column type surface grinder

3468 ~ 34188 AHD / PNC

-

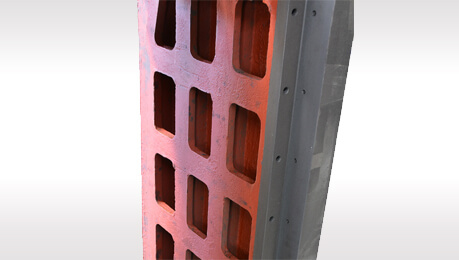

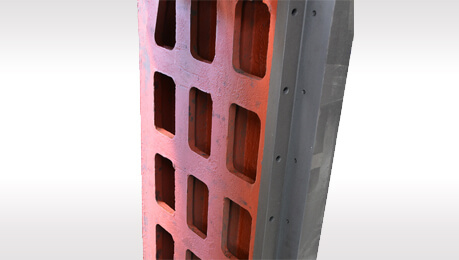

Upper column

Enhanced net type double wall structure ensures machine solidity and grinding precision

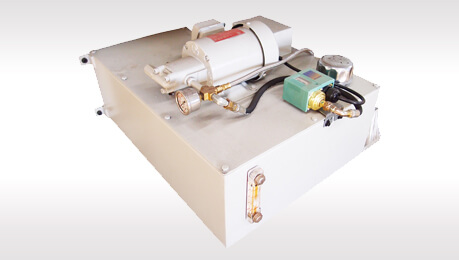

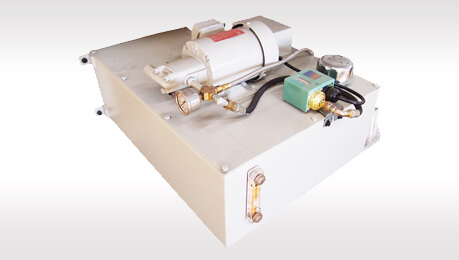

Hydraulic weight balancing assists reliving the loads of vertical feed ball-screw. It assures the sensitivity and accuracy of vertical feed, as well as extends the life-span of servo motor & vertical ball-screw.

-

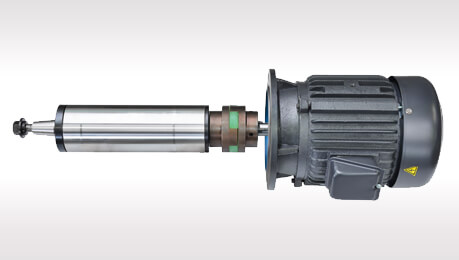

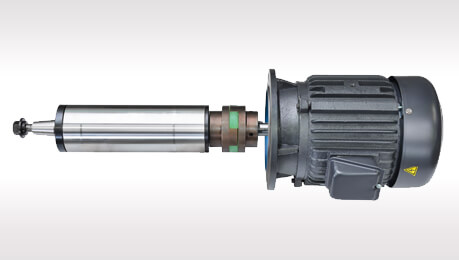

Spindle & Motor set

High precision in-house assembled cartridge type spindle set uses 6 super precision CP4 grade angular ball bearings, sealed with permanent lubrication. This structural superiority empowers the spindle to grind with low noise, low heat rise, and high precision

V3 grade motor is integrated with spindle set via couplings for direct transmission, to obtain maximum torque and reduce vibration

-

Control system (AHD type)

Numerical Control system that utilizes AC servo motor on vertical feed

Encoders equipped on servo motor and high precision ball-screw ensure superior sensitivity and accuracy of wheel positioning

Automatic cross feed travel limits can be set via control panel

Multiple vertical feed modes: A. Automatic B. Manual C. Micron pulse generator

-

-

Model SGS-3468

AHD / PNCSGS-3488

AHD / PNCSGS-34128

AHD / PNCSGS-34188

AHD / PNCWorking Surface of table. WxL 850x1700 850x2200 850x3200 850x4700 Max. grinding surface WxL

850x1700 850x2200 850x3200 850x4700 Max. Horizontal travel of table. 1850 2350 3350 4850 Max. Cross travel of table. 870 Distance between table surface and spindle center 950 Table speed 5~25 M / min (16~80 fpm) Automatic crossfeed of saddle (60HZ) 0~38 Vertical handwheel (1 gra) 0.002 Crossfeed handwheel (1 gra) AHD (0.02) / PNC (0.002) Longitudinal travel adjustable (from~to) 150~1800 150~2300 150~3300 150~4800 Crossfeed travel adjustable (from-to) 0~850 Spindle motor 15HP x 6P Hydraulic pump motor 10HP x 6P 15HP x 6P Crossfeed motor AHD: ¼HP x 6P PNC: AC SERVO Downfeed motor AC SERVO Grinding wheel (ODxTxID) 510 x 50 x 127

*510 x 75 x 203.2Spindle speed 60/50HZ 1150 RPM / 60 HZ

960 RPM / 50 HZCoolant motor ¼HP Net Weight 10000 kgs 11500 kgs 15500 kgs 25000 kgs Gross Weight 11500 kgs 13500 kgs 18000 kgs 28000 kgs Packing dimensions (L x W x H) 6500 x 3300 x 3000 7600 x 3300 x 3000 10500 x 3300 x 3000 14000 x 3300 x 3000 In specification, if there is a * mark in front of item, it is an optional specification.

We follow a policy of continuous improvement of all our products, and reserve the rights to change specifications, mechanìcs, or designs at any time without notice or oblìgation.